Digital Product passport Management: Common Questions Answered

Digital Product Passports (DPPs) are reshaping how Swedish businesses manage product data, meet regulations, and support sustainability efforts. These digital records store essential product lifecycle details – from materials and manufacturing to disposal – accessible via QR codes, NFC tags, or RFID chips. Here’s why they matter:

- Transparency: Centralized data enables clear visibility into supply chains, boosting trust.

- Regulatory Compliance: Simplifies adherence to EU and Swedish rules, like the Ecodesign for Sustainable Products Regulation.

- Sustainability Goals: Supports repair, reuse, and recycling by providing detailed product insights.

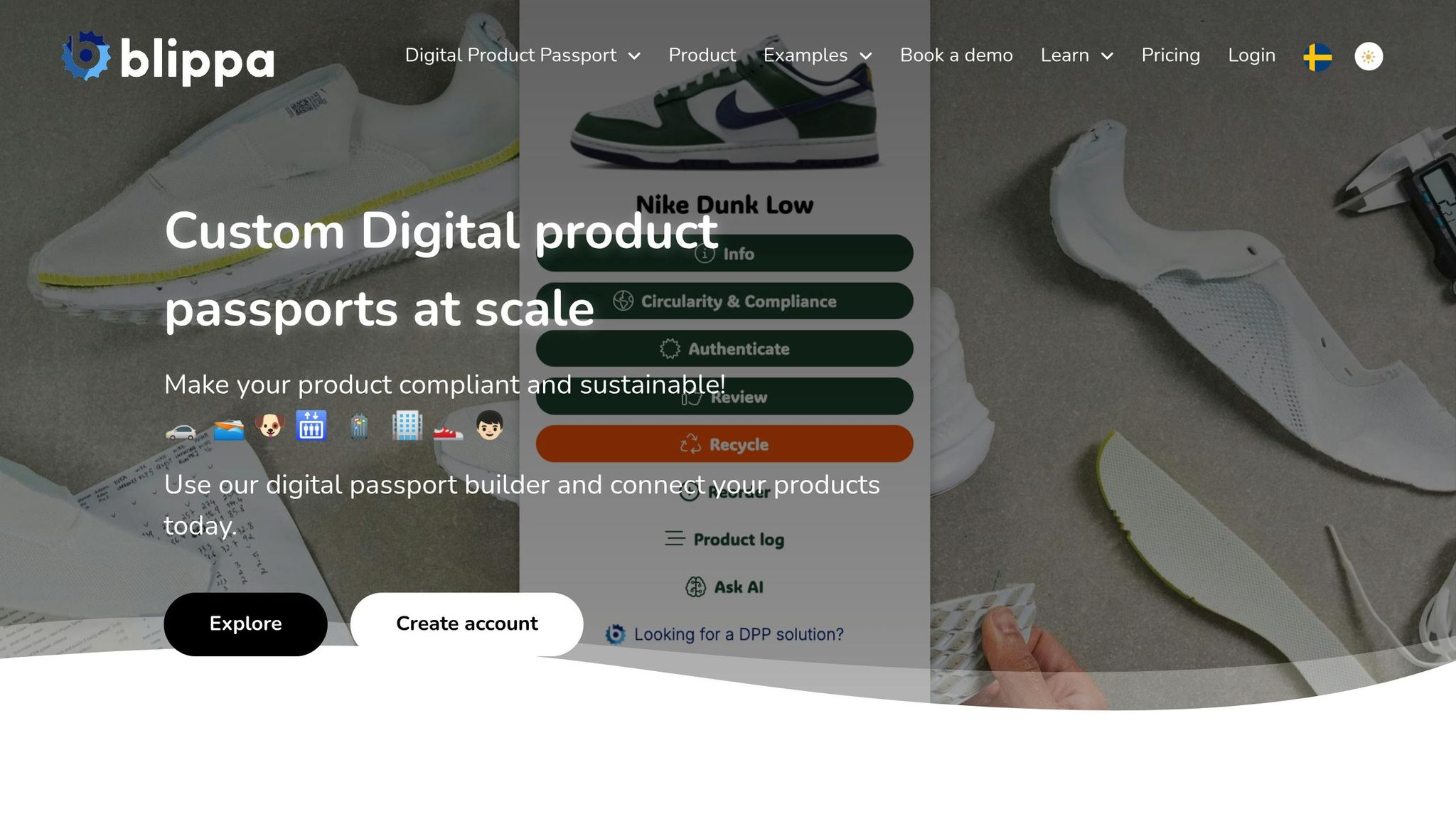

Industries like textiles, electronics, automotive, and furniture are leveraging DPPs to meet rising demands for traceability and eco-conscious practices. Tools like Blippa simplify DPP implementation with no-code platforms, templates, and integrations into existing systems, making it easier for businesses to get started.

While DPPs offer numerous benefits, challenges include data management, integration costs, and staff training. However, platforms like Blippa address these with features like version control, secure user access, and seamless system integration. For Swedish companies, adopting DPPs isn’t just about compliance – it’s about staying competitive in a world increasingly focused on transparency and accountability.

What Is the Digital Product Passport? | Everything There Is To Know About the DPP Up Until Now!

Core Benefits of Digital Product Passports

Digital Product Passports (DPPs) offer far more than a convenient way to store data. For Swedish businesses, especially those navigating increasingly complex regulations, these tools can drive efficiency, boost competitiveness, and enhance operations in ways that directly impact profitability.

Better Transparency and Traceability

DPPs centralise all product-related data, offering businesses real-time, end-to-end visibility across their supply chains. This means Swedish companies can follow materials from their origin to the final stages of a product’s life, spotting potential issues before they become costly problems.

By reducing the need for manual tracking, DPPs minimise errors and streamline processes. For instance, a textile company in Gothenburg can instantly verify the certification of organic cotton, while an electronics manufacturer in Stockholm can confirm the sourcing of conflict-free minerals. This level of transparency not only builds trust with consumers but also addresses scepticism around sustainability claims. It’s a powerful way to strengthen brand loyalty in an era where customers demand proof of ethical practices.

Support for Sustainability and Circular Economy

DPPs are a cornerstone for advancing circular economy goals by providing detailed insights into a product’s composition, making repair, reuse, and recycling more efficient.

Access to lifecycle data allows Swedish companies to pinpoint durable materials, choose reliable suppliers, and uncover ways to reduce waste. This isn’t just about making greener choices – it’s about measurable improvements that align with Sweden’s commitment to environmental leadership.

Moreover, DPPs enable end-of-life planning right from the design phase. For example, battery manufacturers can include precise recycling instructions, while furniture makers can specify adhesives that allow for easy disassembly. This forward-thinking approach ensures products are created with disposal and reuse in mind, reinforcing Sweden’s global reputation for environmental responsibility.

Compliance with EU and Swedish Regulations

For businesses dealing with complex regulations, DPPs simplify compliance. Automated data capture ensures seamless reporting under frameworks like the EU’s Ecodesign for Sustainable Products Regulation (ESPR), eliminating the need for redundant data collection.

Having continuous and accurate records makes audits less stressful and ensures adherence to chemical, labour, and environmental standards. With verified data flowing directly into regulatory submissions, the risk of errors or omissions is significantly reduced compared to manual processes. This not only helps Swedish businesses avoid penalties but also upholds their reputation for maintaining high compliance standards.

Steps to Implement and Manage Digital Product Passports

Swedish businesses can adopt Digital Product Passports (DPPs) step-by-step by making use of their current systems and data. Here’s a breakdown of how to prepare, implement, and integrate DPPs effectively.

Preparation: Conducting Data Audits

Start with a thorough data audit to figure out what product information is already available and where the gaps are. Map your existing data across systems like ERP platforms or compliance databases, and document any regulatory requirements that need to be addressed. This process will help you identify missing details that may require manual input.

Focus on your most impactful product lines for the first phase of DPP deployment. For instance, a furniture maker in Småland might prioritise FSC-certified wood products, while an electronics company in Stockholm could start with items containing critical raw materials.

Evaluate the quality and format of your data. Determine what is already digitised and well-organised versus what exists only in paper records or scattered emails. This step will clarify where manual data entry is needed and where automated tools can make the process smoother.

Using Blippa for DPP Implementation

Blippa’s no-code platform makes creating DPPs straightforward. With its drag-and-drop editor, you can build detailed product passports by adding specifications, sustainability metrics, supplier details, and compliance documents – all without needing to write code.

Pre-built templates designed for specific industries, such as textiles or electronics, can help you get started quickly.

The platform also generates QR codes automatically and offers cloud-hosted passports with features like version control and automatic notifications. These tools make it easier to integrate DPPs into your existing workflows.

Blippa also supports user and role management, allowing you to assign access to team members who need to update technical details or environmental data as your DPP program grows.

Integration with Existing Systems

To centralise your product information, integrate DPPs with your current business systems. Blippa’s platform supports third-party integrations and includes features like notifications and role management to simplify updates.

Team members can receive email or SMS alerts about changes, ensuring everyone stays informed. Additionally, the option to use a custom domain for your product passports helps maintain consistent branding and enhances customer communication.

sbb-itb-256b3ff

Industry-Specific Applications of Digital Product Passports

Different industries in Sweden face unique challenges when implementing Digital Product Passports (DPPs), especially given the country’s strict regulations around transparency and sustainability. Each sector requires tailored solutions to meet compliance standards and improve traceability.

DPPs in the Textiles Industry

In Sweden’s textile sector, transparency around material origins, production methods, and environmental impact has become a top priority. Digital Product Passports make it possible to track data at every stage – from sourcing raw fibres to recycling at the end of a product’s life.

A textile-focused DPP typically includes details such as fabric composition, dyeing methods, and water usage. This information aligns with Sweden’s push for sustainable fashion and empowers consumers to make more informed choices. For instance, Swedish brands can integrate certifications like GOTS (Global Organic Textile Standard) or Oeko-Tex directly into the passport, simplifying verification for both retailers and buyers.

Additionally, these passports can provide care instructions tailored to prolong garment longevity. They include specifics like recommended washing temperatures in Celsius, suitable detergents, and repair tips, all of which contribute to Sweden’s circular economy goals.

Blippa’s textile templates come pre-configured with fields for tracking material composition, supplier details, and sustainability metrics. The platform also features an integrated QR code generator, allowing brands to embed these passports directly into garment labels. This ensures that essential product information is accessible throughout the product’s lifecycle.

DPPs in Electronics and Batteries

For electronics manufacturers in Sweden, compliance with complex regulations around hazardous materials, recycling, and supply chain transparency is a constant challenge. Digital Product Passports offer a structured way to document adherence to directives such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment).

Battery manufacturers, in particular, can use DPPs to capture crucial details like battery chemistry, capacity (Ah), charging cycles, and disposal guidelines. These passports not only help consumers better understand product performance but also ensure compliance with Swedish and EU recycling standards.

Electronics DPPs can also track critical raw materials – such as lithium, cobalt, and rare earth elements – providing information about their sources and conflict mineral certifications. Additionally, they can include repair information, such as spare part availability and repair manuals, supporting Sweden’s right-to-repair initiatives and extending product lifespans.

Blippa’s platform offers features like version control and real-time notifications, which are particularly useful in the electronics sector. These tools help manufacturers manage firmware updates, safety recalls, and specification changes across different product lines.

Traceability Technologies and Tools

The successful implementation of Digital Product Passports depends on effective identification technologies. QR codes are one of the most accessible options, requiring only a smartphone camera to access passport information quickly.

Other technologies, such as NFC chips and RFID tags, are also commonly used, especially in inventory management and supply chain tracking. These tools provide enhanced security and longer-range scanning capabilities, making them suitable for various industries.

Blippa’s no-code platform simplifies the process of linking physical products to their digital passports. It integrates seamlessly with existing Swedish systems, ensuring that DPPs can be deployed efficiently across different sectors while meeting local requirements for traceability and transparency.

Advantages and Limitations of Digital Product Passport Solutions

For Swedish businesses, understanding the benefits and challenges of Digital Product Passport (DPP) platforms is crucial for making informed decisions. While DPPs bring increased transparency and help with regulatory compliance, they also come with hurdles that require thoughtful planning.

Pros and Cons of DPP Platforms

| Advantages | Limitations |

|---|---|

| Enhanced Transparency: Provides full visibility into a product’s lifecycle, from raw materials to disposal, meeting Swedish consumers’ demand for openness. | Implementation Complexity: Setting up the system involves extensive data collection and integration efforts. |

| Regulatory Compliance: Automates adherence to EU and Swedish regulations. | Data Management Challenges: Keeping information accurate and updated across multiple product lines can be resource-heavy. |

| Supply Chain Traceability: Enables real-time tracking of materials and components during production. | Technology Dependencies: Requires reliable digital infrastructure and internet access for passport functionality. |

| Consumer Trust: Builds credibility by offering direct access to detailed product information, aiding purchasing decisions. | Staff Training Requirements: Teams need time and resources to learn new systems and workflows. |

| Sustainability Reporting: Simplifies gathering environmental impact data to support corporate sustainability goals. | Integration Costs: Linking DPP platforms with existing ERP and PIM systems may demand technical expertise. |

| Circular Economy Support: Promotes reuse, repair, and recycling by providing detailed component data. | Data Security Concerns: Protecting sensitive supply chain and product data requires strong security protocols. |

Overcoming Challenges with Blippa

Blippa offers practical solutions to help Swedish businesses navigate the limitations of DPP platforms. By using a no-code approach, Blippa simplifies the adoption process while ensuring compliance and functionality.

The platform’s no-code editor removes the need for advanced technical skills during setup, offering pre-designed templates that align with Swedish standards. This makes the initial implementation more manageable for businesses of all sizes.

Blippa also includes version control tools, making it easy to keep product information up to date. Whether specifications or compliance rules change, businesses can update passports across entire product ranges quickly and efficiently.

For integration, Blippa connects seamlessly with existing ERP and PIM systems, automating updates and reducing manual effort. This ensures that the platform fits smoothly into existing workflows, saving time and resources.

Data security is another area where Blippa excels. Role-based access controls and user management features ensure that only authorised personnel can edit sensitive information. This allows Swedish companies to establish secure approval workflows while staying agile enough to adapt to market demands.

Key Takeaways on Digital Product Passport Management

Digital Product Passports (DPPs) are transforming how Swedish businesses handle transparency and supply chain management. By creating digital records that track products throughout their entire lifecycle, these tools are reshaping the way companies operate.

One major reason for this shift is compliance. With stricter EU regulations, Swedish companies are turning to DPPs to meet legal requirements and avoid disruptions in the market. These passports simplify compliance reporting, reduce administrative headaches, and help businesses align with environmental standards more efficiently.

But the benefits don’t stop at compliance. DPPs also support sustainability efforts by providing detailed information about product components. This makes it easier to repair, refurbish, and recycle products, reinforcing the circular economy. For Swedish manufacturers, DPPs offer an opportunity to be transparent about carbon footprints, material sourcing, and end-of-life processes, which can strengthen trust with consumers and stakeholders.

A no-code approach makes adopting DPPs easier for businesses, even those without advanced technical expertise or complex IT systems. This accessibility helps more companies take advantage of the benefits DPPs offer.

However, successful implementation depends on system integration. DPPs need to seamlessly connect with existing ERP and PIM systems to ensure consistent data and smooth business operations. Without this integration, the efficiency of managing product data may be compromised.

DPPs also show their flexibility by being useful across a range of industries, from textiles to electronics and batteries. Each sector can adapt these digital tools to meet specific regulatory and consumer demands.

To fully unlock the potential of DPPs, maintaining accurate and up-to-date product data is crucial. Features like version control play an important role in managing the complexity of this information. Ultimately, DPPs not only simplify regulatory compliance and promote sustainability but also require careful data management to deliver their full value.

FAQs

How do Digital Product Passports support Sweden’s transition to a circular economy?

Digital Product Passports (DPPs) are an important step forward in Sweden’s push for a circular economy. They help extend the life of products by making repairs and refurbishments more straightforward, encourage the use of recycled materials, and make sorting and recycling more efficient, ultimately cutting down on waste.

With clear and accessible product information, DPPs give both businesses and consumers the tools to make choices that are better for the environment. This approach aligns perfectly with Sweden’s focus on sustainability and forward-thinking solutions.

What are the key steps for Swedish businesses to successfully implement Digital Product Passports?

Swedish companies should begin by evaluating their existing product data management systems to pinpoint any shortcomings in addressing sustainability and traceability needs. This step ensures they understand what adjustments are necessary to comply with both Swedish and EU regulations.

Once gaps are identified, it’s crucial to establish clear objectives for adopting Digital Product Passports (DPPs). These goals should align with the regulatory framework while supporting the company’s operational priorities. For a smooth transition, consider using a no-code platform like Blippa. This type of platform integrates effortlessly with current ERP and PIM systems, simplifying data management and collection processes.

To ensure success, train your team on DPP standards and practical applications. A phased rollout can help ease the transition, allowing time to address challenges and refine processes as you go.

How does Blippa protect data and manage user access in Digital Product Passport management?

Blippa places a strong emphasis on data security and user access management to protect the integrity of Digital Product Passport (DPP) operations. Sensitive information is safeguarded throughout its lifecycle with advanced encryption techniques, ensuring it remains secure at all times.

To streamline access management, Blippa offers flexible permission settings. Organisations can tailor these settings to assign roles and restrict access based on individual responsibilities. This approach not only protects critical data but also ensures that operations run smoothly by granting access only to authorised personnel.